Many clients come to us with the same question: “Can Odoo really handle my production process?” .The short answer is yes — but there are a few important things to keep in mind.

In this post, we want to offer a realistic and practical overview of how to start working with Odoo's manufacturing module without overcomplicating things. Later on, we can certainly make it more complex, but we always recommend entering this world step by step.

What does the Odoo manufacturing module cover?

Odoo allows you to manage manufacturing processes with a fair amount of flexibility. Out of the box, it includes:

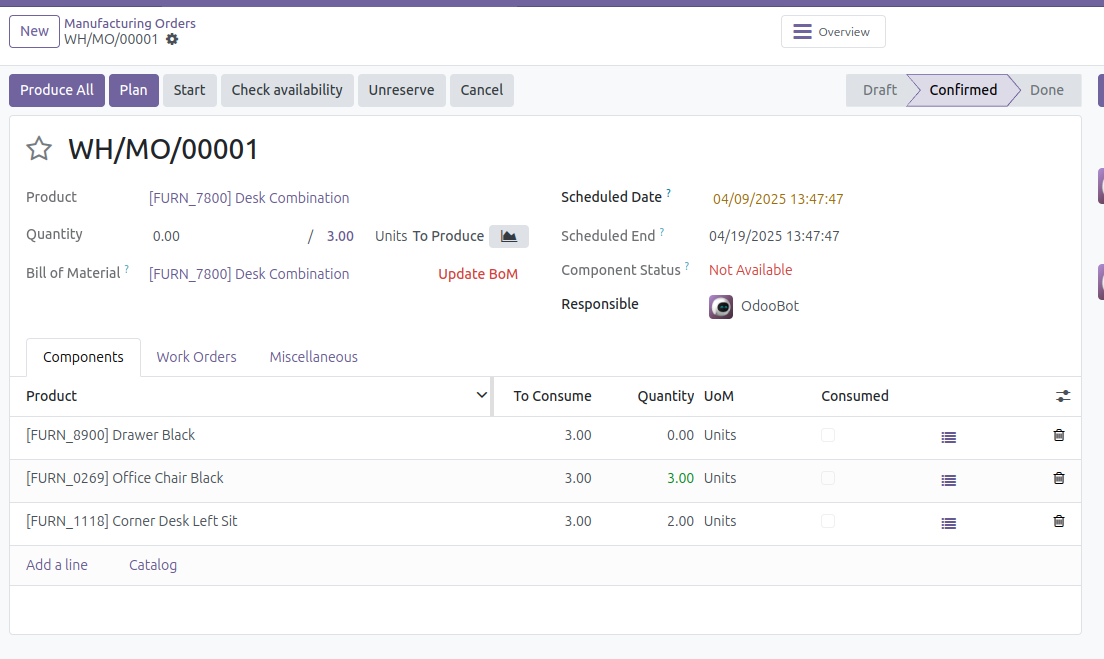

- Manufacturing Orders, which define what product to produce, in what quantity, and using which components.

- Bills of Materials (BoM), where the required components are listed.

- Automatic stock movements, both for components and finished products.

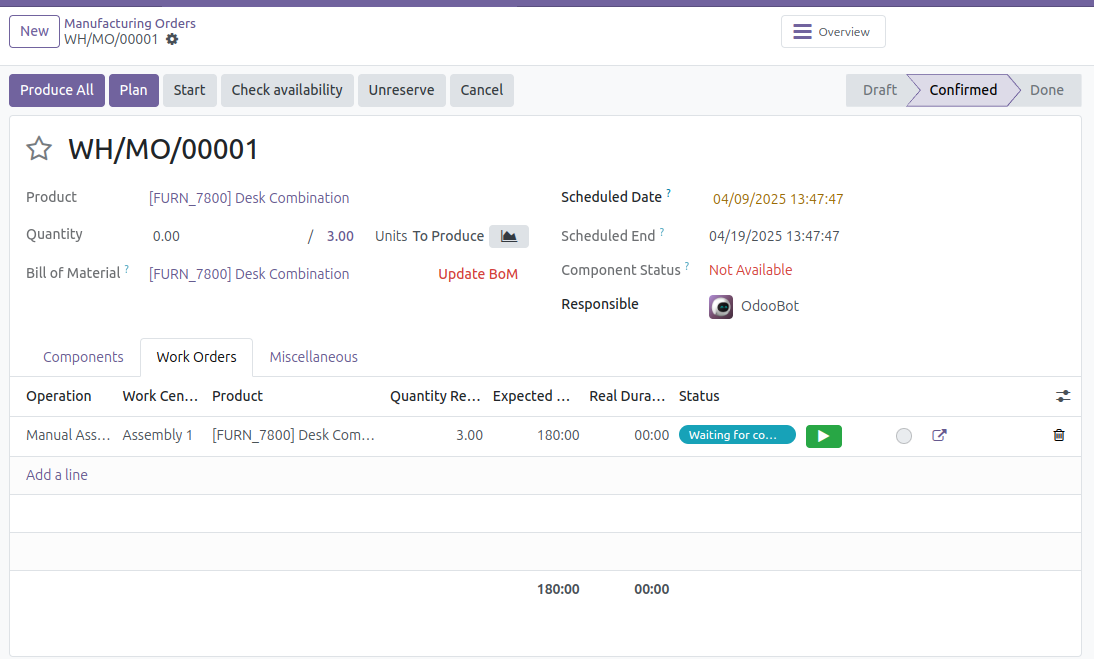

- Work centers and routing, if you want to manage production in phases.

- Production costing, calculated based on materials, operations, and time (if configured).

- Basic planning, allowing you to track pending orders and overlaps.

For many small and medium-sized manufacturing businesses, this already covers 90% of their initial needs.

What workflow do we recommend to get started?

We've seen many companies try to replicate their exact physical production process in Odoo, and end up frustrated. Our recommendation is to start with a simple flow:

- Create manufactured products with a basic Bill of Materials.

- Activate the manufacturing module without using routing or work centers.

- Manually create manufacturing orders and register component consumption.

- See how Odoo automatically moves stock when confirming production.

- Enable additional steps only if the process truly requires it.

This approach gives you control, traceability, and automation — without overloading the initial setup.

When does it make sense to go a step further?

Once the basic flow is stable, you can enable more advanced features:

- Work centers and operations, if your production involves clear phases.

- Quality module, to record checks during the process.

- Advanced planning, if you face bottlenecks and want to optimize timings.

- Preventive maintenance, if you want to manage your machines from Odoo.

But we always recommend introducing these elements progressively — never all at once. Keep in mind that Odoo includes advanced features like demand-driven planning (DDMRP), but we believe these steps should come only after the basics are well established.

Conclusion

Odoo's manufacturing module is powerful, but the key is to start with a simple and realistic implementation. You don’t need to activate every feature from day one. The goal is to have visibility, traceability, and control over your production process. The rest can be fine-tuned over time.

And above all: if something doesn’t fit perfectly out of the box, there are always ways to adapt it. But first, it’s essential to understand the core logic of the system.